wall panel making machine

Basic Info

Model No.: cnzt-003

Product Description

galvanized steel Wall Panel roll forming machine

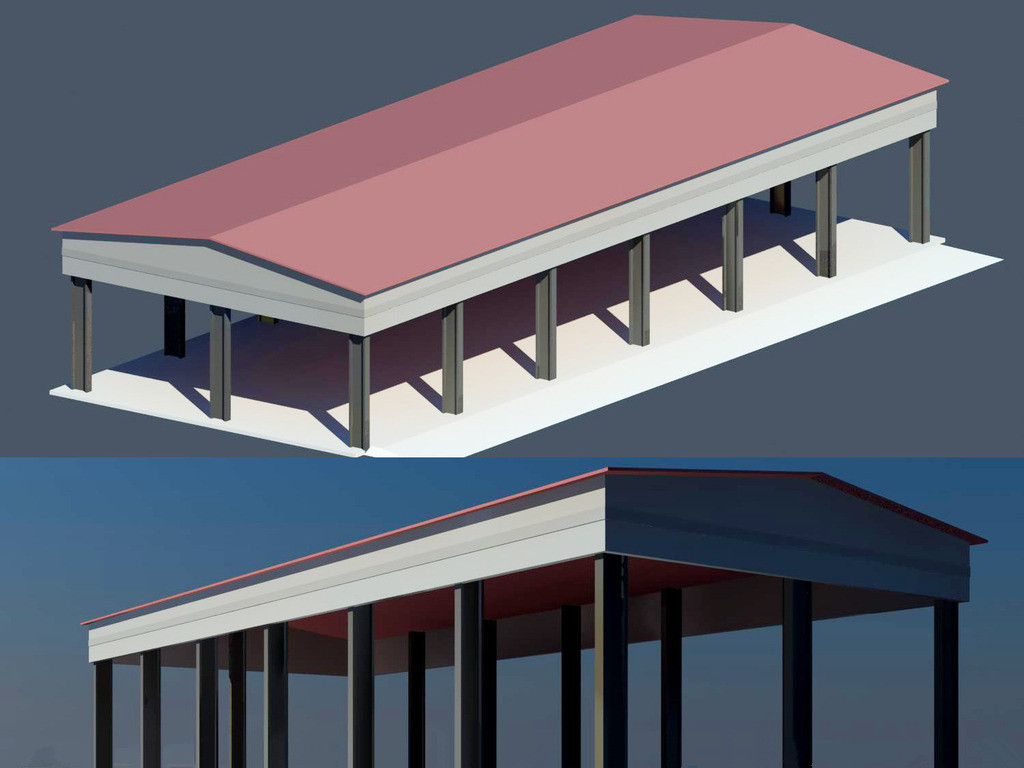

The products galvanized steel wall panel roll forming machine produceare extensively used in building steel-structure large-scale warehouses, plants, supermarkets, shopping malls, trade markets, stadiums, holiday villages, sanatoriums, hotels, villas, residences and different kinds of greenhouses.

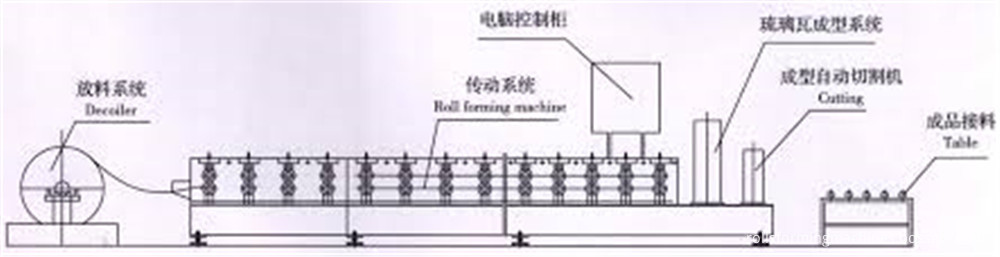

Processing flow diagram of wall panel making machine

Manual decoiler -Feeding material into machine -Roll forming machine -Measure length -Hydraulic cutting -Finished Products

Technical parameters of wall panel making machine

Decoiler

The thickness of the raw material (steel plate) can be 0.3 - 0.8 mm.The loading capacity can reach 3T . It is used to support the steel coil and uncoil it in a turntable way.

Uncoiling width: 500mm

Inner diameter: 450-550mm

Main roll forming machine:

Feeding and flatting will make sure the steel is neat clean and straight.The machine adopts middle plate welded Memorial arch frame type, and is driven by gear . We can design voltage as customer`s request.

Roller fixer : Guide column

Speed: 5-50m/min

Material of rollers: GCr12MoV

Material of shafts: 45# steel with tempering

Diameter of shafts: φ40mm

Shearing machine:

Material of blades: Gcr12 quenched

Frame : Pillar style with rack

Electic Control System:

Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime.

packing :

1. One 20ft container for loading one set machine with manual decoiler.

2. The whole wiped anti rust oil ,PLC controller covered by foam film.

3. Spare parts and some small parts packed in plastic tooling box.

4. All components of Deck Roll Forming machine fixed by steel wire.

FAQ:

1.How to get a quotation of wall panel making machine?

Give me the profile drawing and thickness ,this is the important.

Other spicific requirements is welcome,such as the speed,power and voltage you want.

2. Terms of payment:

30% T/T, Balance to be paid before shipping after inspection.Also we accept the payment L/C, O/A , D/P.

4. What is your after-sale service?

wall panel roll forming machine's warranty period is 12months,if the broken parts can't be repaired,we can send new to replace for free,but you need to pay the express cost yourself.we supply the technical support for the whole life of the used metal roof panel roll forming machine.

5. You are trade company or factory?

We are trade company but we also have own factories. Building trade company is just for exporting various types of cold roll forming machines.

6. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour), then we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

Product Categories : Roofing Sheet Roll Forming Machine > Roof and Wall Panel Roll Forming Machine